Deciding What To Measure

When it comes to purchasing a replacement hot tub cover, taking proper measurement is the key to receiving the perfect product. Read through these step by step directions to ensure that you are taking accurate measurements for your new spa cover. If you have any questions whatsoever about how to measure a spa cover feel free to contact our team for help. We are on stand by and happy to assist you in ordering the right product for your hot tub or spa.

If any of the following apply to you, measure your existing cover:

- Cover must be in decent condition. Natural wear and tear is fine.

- Cover has not warped, become waterlogged, or changed shape since its purchase.

- You are happy with the way the current cover fits.

If any of the following apply to you, measure your hot tub:

- You have no existing cover.

- Your current cover is warped, has become waterlogged, or changed shape since its purchase.

- Unhappy with the way your current cover fits.

How to Measure

Round up measurements to the nearest half inch or inch. A cover that is 1-2 inches too large will fit just fine but a cover that is too small will decrease the insulation. If your measurements are close to being perfectly square (ie: 78.5” x 78”), it probably is a perfect square.

Where to Measure

Choose which installation type looks most like yours:

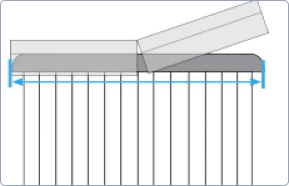

Classic spa cabinets

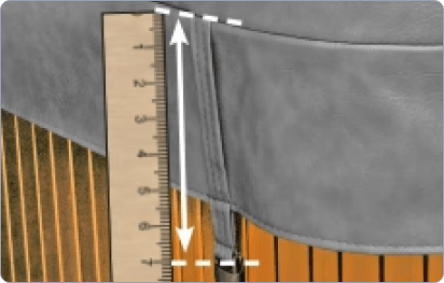

Measure the widest points on the acrylic lip shown by the arrows.

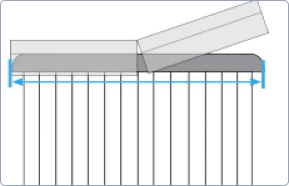

Spa cabinets with top rail

Measure the widest points on the top rail shown by the arrows.

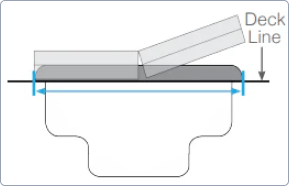

In ground spas

Measure the widest points above ground shown by the arrows.

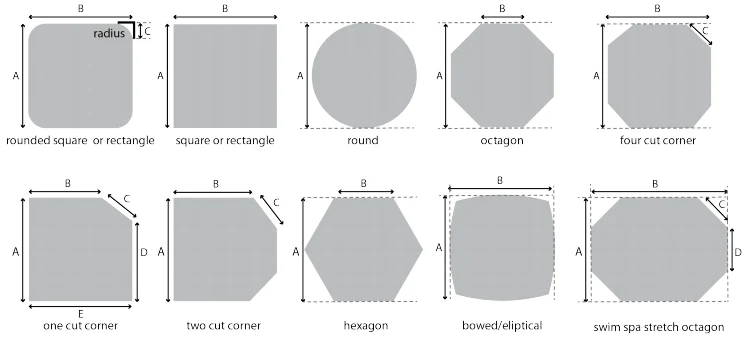

Choose a Shape and Measure

Choose which installation type looks most like yours: Hot tubs come in various shapes and sizes. Use our comprehensive chart to select the right dimensions for your spa.

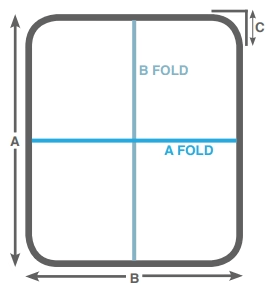

Choosing a Fold/Hinge

Understanding the folds and hinges of spa covers is crucial. Select the appropriate fold that suits your setup.

- An "A Fold" splits the A dimension in half.

- A "B Fold" splits the B dimension in half.

- For a perfectly square cover, no fold/hinge is needed.

- Determine the location of the control panel; covers usually fold away from it.

- The longer side typically gets folded in half, but not always.

- Check for obstructions (e.g., fence) that might affect how the cover opens and closes.

Considerations

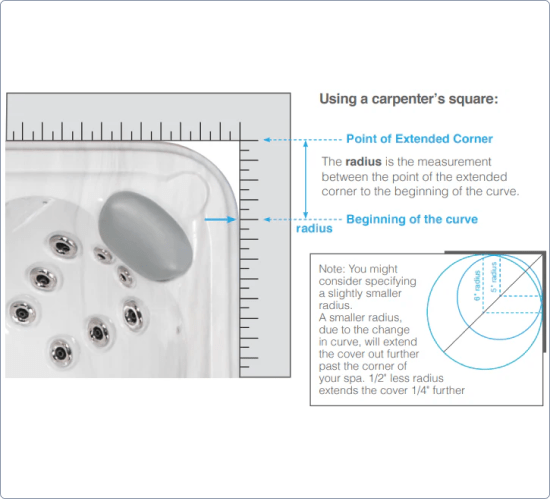

Using a carpenter’s square

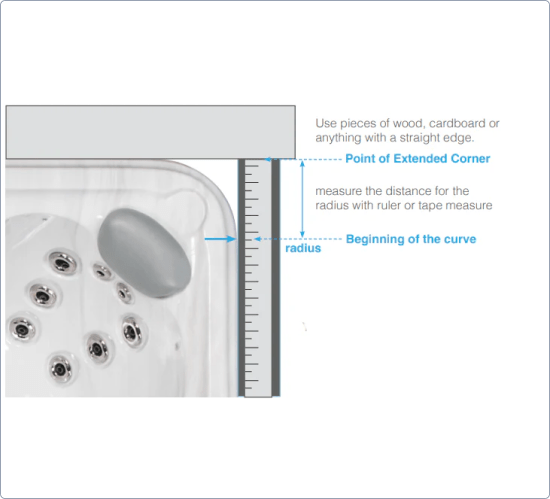

If you don’t have a square handy:

Have you completed your measurements? If so, you’re ready to purchase your custom spa cover. Browse our customization options and place your order today

Our Quality

It is easy for a website to claim they have the best quality but at MySpaCover we guarantee it. We utilize only the highest quality materials and the most sophisticated processes to offer the best covers available online. Here is how our covers compare to the competition:

MYSPACOVER

Our heavy-duty handles come standard and are double stitched using marine grade vinyl to ensure the highest durability and most attractive aesthetics.

Our standard straps are double stitched and are also produced with marine-grade vinyl.

We double stitch every seam and hinge to ensure your spa cover can be used for years to come.

Other Guys

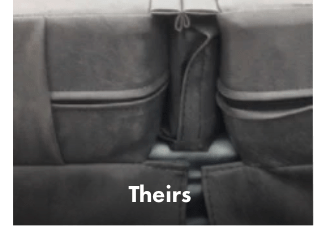

Their cheap handles are more prone to wear and tear and are known to rip off within the first two years plus the appearance speaks for itself.

Our competition uses low-quality straps that are prone to breakage and often times do not match the color of the spa cover.

Their use of single stitching and exposed shells can ultimately cause cracking and heat loss, costing you more on your electric bill.

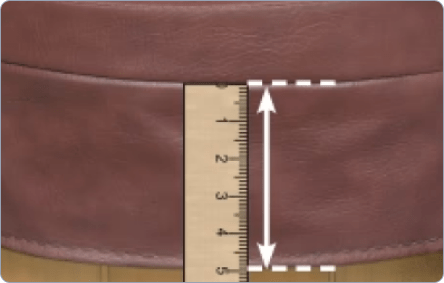

The Underside

The underside of a spa cover is often overlooked. However, this is the material that is in constant contact with high temperatures and the chemicals in your spa. The life of your spa cover depends on a high-quality spa underside. We don’t cut corners like the other guys so you can trust that our 6 mil plastic wrap is vapor sealed to the core and will keep the heat out.

MySpaCover utilizes an 11oz PVC coated poly that, after years of rigorous testing, has proven to be the best possible material to withstand constant high temperates and chemical exposure.

Beware of mesh bottoms used by competitors as this type of material is meant to cut costs and is prone to failure.

We’ve found a few great alternatives to your selected spa cover that can reach you even quicker!

Here are the closest available alternatives based on your preferences.